If required, the troughs can be fitted with perforated plates that help to sieve out residual abrasive or sand.

When used as scanning conveyor, the systems are specially designed for low-noise transport. In this case, vertical acceleration is below 1, which stops the parts lifting away from the base. This also helps stop the castings from being damaged.

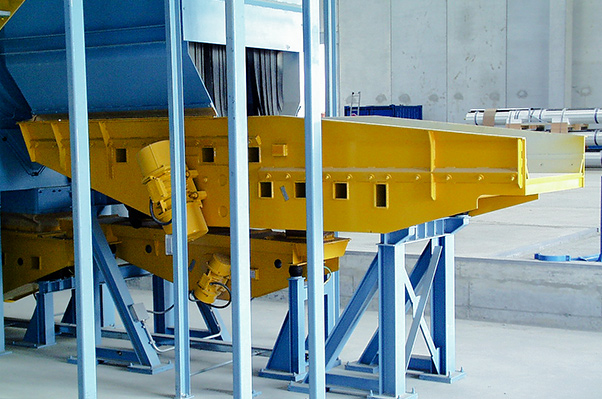

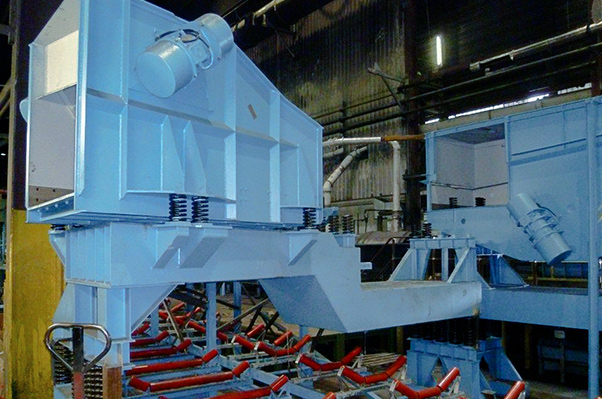

Depending on the space available and the conveyor length, the troughs are designed as either single-mass (FVE) or crank (FKL) systems.

The drive uses vibrator motors (FVE) or a slider-crank drive with V-belt transmission (FKL).

Benefits compared to other systems:

- No damage from sharp metal parts

- No catching, as the trough is enclosed

- Higher abrasion and heat resistance and therefore lower maintenance costs and longer maintenance intervals

- Fewer moving parts that can fail