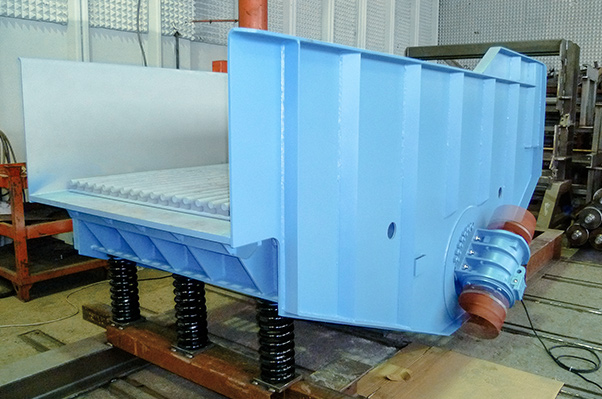

To generate the highest possible level of separation, our tried-and-tested system utilizes at least two (or more) consecutive shake-outs that can be run with independent travel speeds and angles of vibration, as appropriate to the casting program.

We use the principle of high frequency vibration in the downstream (second) shake-out. This approach achieves separation despite the low amplitude and also reduces the risk of castings being damaged.

This technology is a huge advantage primarily when most of the sand has already been separated off and the casting is being conveyed directly on the screen decks.

The drive uses vibrator motors or unbalance exciters.